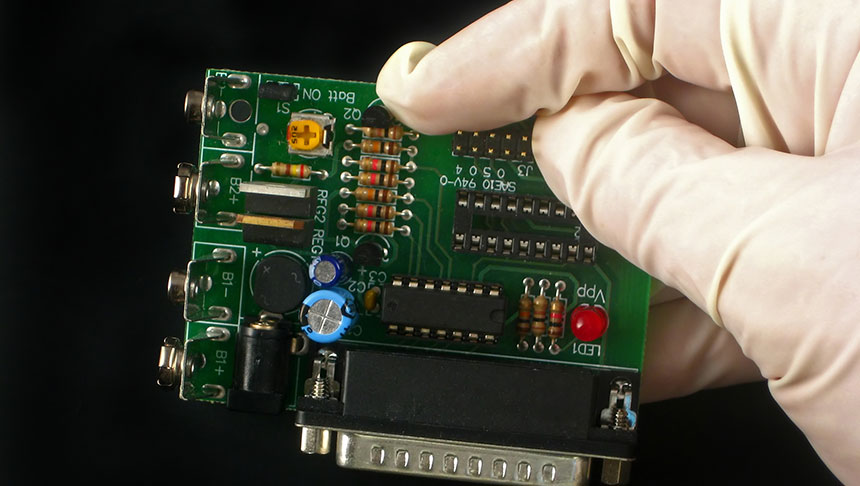

All incoming material is opened and inspected on grounded static mats that comply with ESD standard 4.1, 20-20, EIA625 and Mil Std 1686 with personnel using wrist and heel straps.

All packaging material (bags, bubble wrap, peanuts) are anti-static and meet all applicable commercial and Mil STDs.

All parts post inspection are re-vacuum sealed to prevent moisture & maintain solderability using desiccant and moisture proof bags.

We use the Vacuum Sealer-AMERIVACS Model # AVS-20.

Berman Electronic is in the process of completing our "class 1" clean room and anticipate completion and certification by calendar end. When completed it will be humidity controlled, fully ESD compliant and have the capacity to store over 1500 cubic feet of inventory. All test, measuring and storage equipment in the room conforms to all applicable ESD standards.

To request a copy of our ISO Guidelines & Procedures Manual, click here.

Contact Us

Contact Us

We're standing ready to take on all your challenges. The power of our experience and team of worldwide suppliers gives Berman Electronic Enterprises, LLCthe leverage to meet your unique demands.

Contact Us Now